OMS for Inter Cars: a completely redesigned fulfillment process

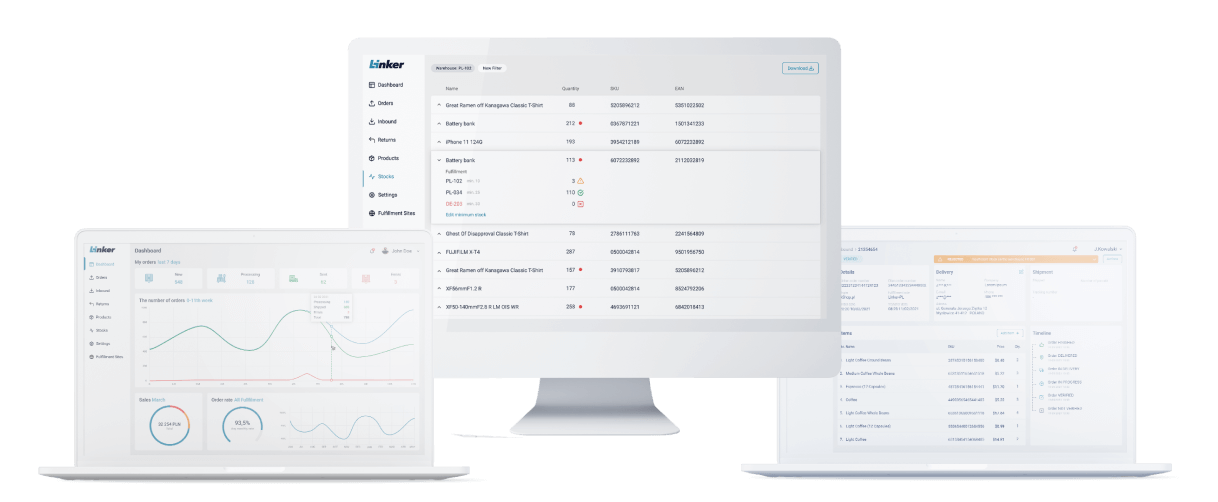

The European leader in automotive spare parts distribution and founders of a multi-tasking logistics platform - joined efforts in a unique project. Check out what we have achieved!

>

3

years of successful cooperation

32

%

logistics cost optimization

📦

dropshipping model additionally implemented

2,5

mln

orders handled

The company

Inter Cars SA, a powerhouse in the automotive spare parts distribution industry, has grown to become one of Europe's largest distributors of parts for passenger cars, vans, and trucks. Over 650,000 indices are distributed in their sales network.

Founded in 1990 by the visionary trio of Krzysztof Oleksowicz, Piotr Oleksowicz, and Andrzej Oliszewski, Inter Cars embarked on a mission to claim the top spot in automotive spare parts distribution. Their journey was marked by a commitment to innovation, with initiatives such as proprietary garage chains, a cutting-edge logistics centre, and Motointegrator.com, a platform seamlessly integrating spare parts and repair services for end consumers.

Today, Inter Cars operates in 18 countries and stands as a publicly traded company listed on the Warsaw Stock Exchange, employing over 13,000 people all over Europe.

The story of a challenge:

Inter Cars' successful entry into the B2C market and the expansion of its own e-commerce channels in Western Europe, coupled with a surge in consumer demand, made the diversification of OMS (order management system) class solutions a necessity - mainly due to the required integrations and the importance of cost optimisation in launching new sales channels.

With a staggering 2.5 million orders per year, they faced a series of challenges, ranging from the major ones:

- the need for effortless management of courier companies specialising in the delivery of different product groups (e.g., tyres or service parts);

- the desire to reduce the cost of delivery to the end customer;

- the quest to improve quality control, returns handling, packaging, and human resources management.

In their work on finding the right solution, they explored available market systems and gained insights from a wide range of offerings, the vast majority of which addressed only part of their complex challenges.

The company recognized the need for a scalable e-commerce logistics platform, one capable of accommodating their rapid growth across B2B and B2C channels while offering the flexibility to adapt to changing demands.

Their ideal solution had to encompass three critical areas: sales (e-commerce stores), warehouse management (WMS), and transportation. It also had to facilitate seamless integration with new sales platforms and provide extensive courier integration. Moreover, they sought to transfer specific WMS operations, such as sorting and packing utilizing mobile terminals, to this new, all-encompassing platform.

Implementation procedure:

Linker Cloud approached and resolved the issues by introducing systematic test rounds.

Before diving into the main project, Inter Cars was keen on ensuring the system's stability and reliability. To mitigate risks, both companies decided to begin with a pilot, focusing on shipping goods to the United Kingdom from their warehouse. This process already relied on communication with ERP systems implemented in Western European markets, as well as basic communication with the Warehouse Management System.

The initial phase, completed in April 2020, served as a great foundation before embarking on the second stage, which involved servicing Motointegrator.com. On top of streamlining and automating between their ERP, WMS, and carriers, Linker Cloud introduced several innovations:

- Complex Communication with WMS: This involved handling issued goods, managing shortages, surpluses, and processing automatic orders.

- Handling Single-Item and Multi-Item Orders: Separating these two types of orders to streamline the process.

- Splitting Customer Demand: Allocating customer demand to different locations.

- New Sorting Module: A module in Linker WMS designed to divide goods from collection containers into dedicated bins corresponding to customer orders.

- Transfer Module for Packing: A module that lists the finished orders in the rack and allows them to be passed on to the packer.

- Handling Discrepancies in the packaging process: A specialized model for addressing discrepancies in the packaging process.

- Shipment Palletization Module: A module for organizing shipments onto pallets.

In November, the first tests of the automated solution took place, simulating the production load of the environment. These tests were carried out at the ILS European Logistics and Development Centre in Zakroczym, in cooperation with ILS, a logistics operator that belongs to the Inter Cars Group. They used both real goods from customer orders and substitute packaging. Warehouse employees, who were crucial in the process, participated in the tests. It was a challenging period due to the severity of the COVID-19 pandemic.

These tests allowed the teams to identify critical issues that only became apparent at scale and to fine-tune the solution based on user feedback. This led to an expansion of the project scope, in pursuit of a "SAFE START-UP."

In total, there were seven testing sessions, and the platform was fully launched and running at the beginning of February 2021.

We were looking for a flexible partner, able to adapt to our needs, and at the same time having the technology to cope with the task, we set ourselves to automate e-commerce shipments.

The Linker Cloud team throughout the sales and implementation process was fully focused on our needs and the goals we set in the implementation project.

Krzysztof Lutrowicz

Supply Chain Director at ILS

The outcome – scale up and out

The implementation of the Linker Cloud platform resulted in impressive outcomes.

The running costs have been reduced by 32% and Inter Cars continues to identify growth opportunities - recently the company successfully implemented a dropshipping model with our help, which proved to be an integral part of its success.

So far, Inter Cars has expanded the product range to over 650,000 SKUs across 300 of its own warehouses, ensuring its position as a leading supplier of automotive parts.

>

3

years of successful cooperation

32

%

logistics cost optimization

📦

dropshipping model additionally implemented

2,5

mln

orders handled

If you are looking for a reliable business partner, you are in good hands now.

Fill in the form to get an offer and see how you can enhance the management of your online business.