Warehousing 3.0 - a completely redesigned fulfilment process

The customer is the largest European distributor of spare parts for passenger cars, vans and trucks, which is growing thanks to over three thousand employees and 12 thousand associates throughout Europe.

>

2

years of successful cooperation

32

%

logistics cost optimization

📦

dropshipping model additionally implemented

2,5

mln

orders handled

About the company

The customer is the largest European distributor of spare parts for passenger cars, vans, and trucks, which is growing thanks to over three thousand employees and 12 thousand associates throughout Europe.

The company is present in seventeen markets of the Old Continent and plans to expand further. For years it has operated on many levels and continues to set new trends in the industry. At the beginning of its existence, the company focused mainly on B2B relations, but for several years it has also been consistently developing retail sales and the e-commerce market.

The story of a challenge:

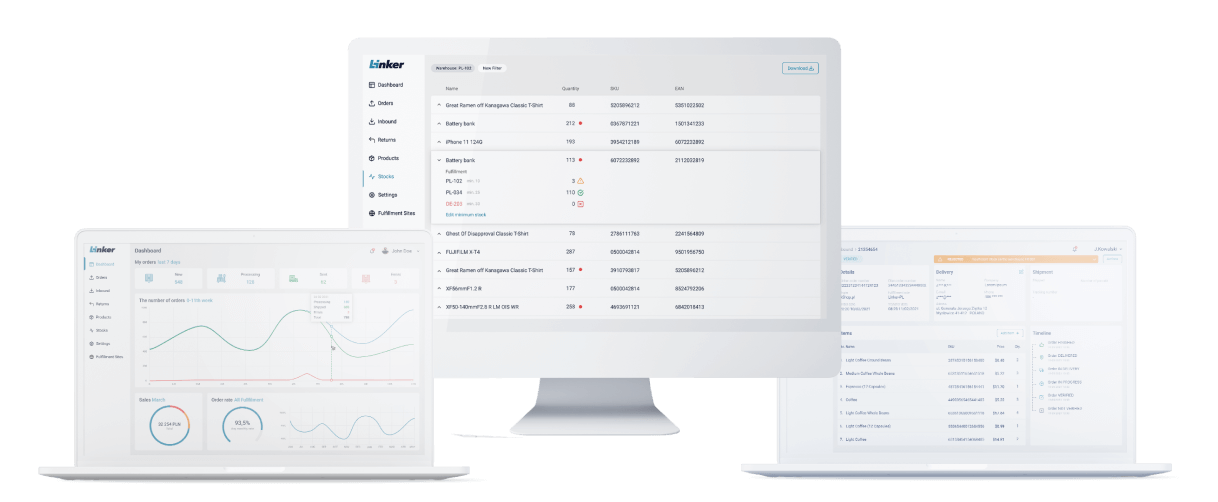

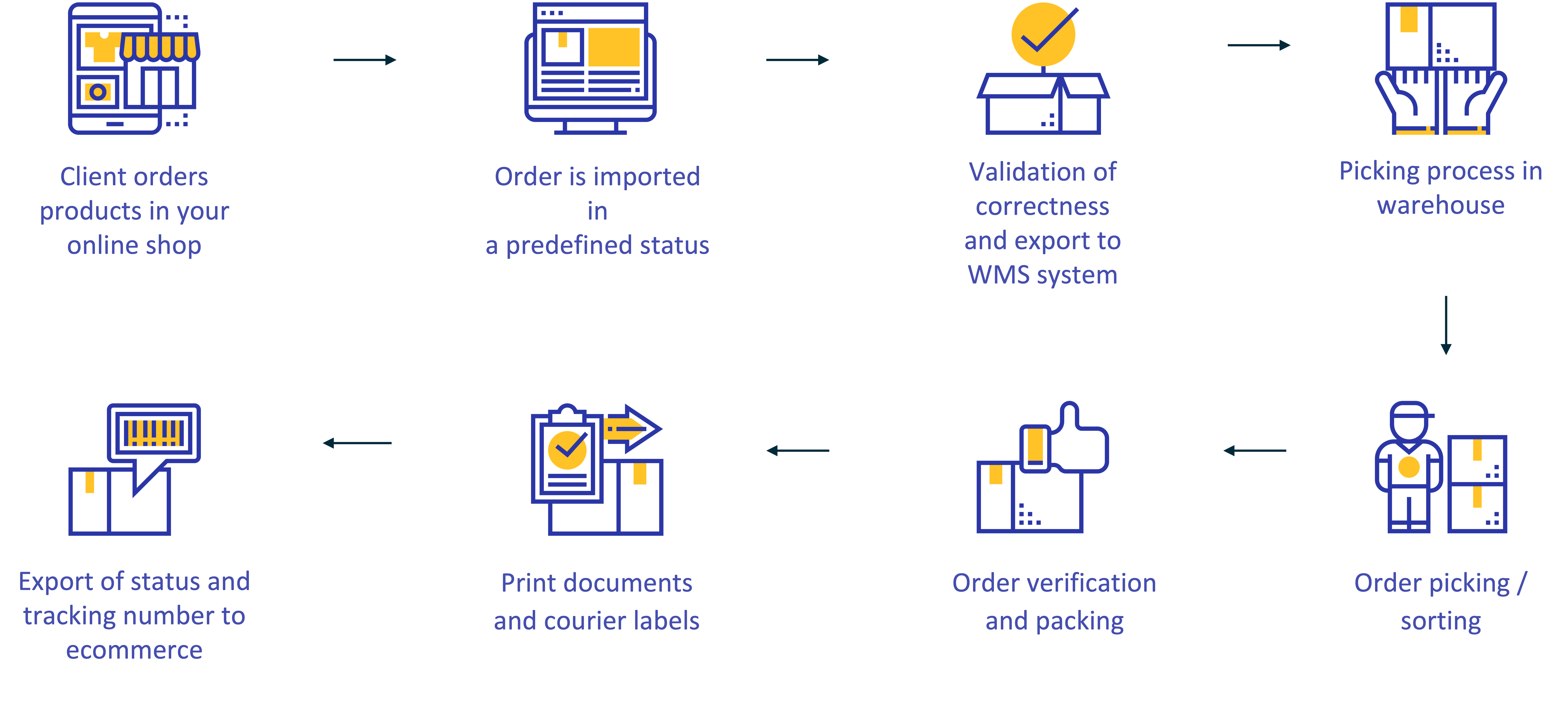

The company was looking for a tool that would combine managing three key areas in e-commerce service, i.e. sales (e-commerce stores), warehouse (WMS) and transport. The chosen solution should significantly reduce the time of integration with new sales platforms and should deliver a wide range of integration with couriers. Another requirement was the possibility of transferring some of the WMS operations to the new tool (especially in terms of sorting and packing processes with the use of mobile terminals).

The main goal of the implementation of the new tool was to gain greater flexibility in introducing changes and development and to build a single, universal B2C order logistics service model for all customer companies.

Due to the very dynamic increase in e-commerce sales (especially on the German market), the service tools used in the company so far quickly became suboptimal. The company internally designed the concept of the solution, which included not only an IT solution but also the construction of a new e-commerce zone with a feeding conveyor that brings internal containers from the storage area and the discharge conveyor - thanks to which the finished parcels move from the packaging area to the release area and loading cars.

Suppliers of the new system were expected to understand the business processes and challenge it faces on a daily basis. It required an in-depth understanding of the described concept, knowledge of the B2C market (especially from the logistics point of view), working out the details together and transferring the whole thing to the functionality of the new system, and, finally, introducing everything to vibrant spare parts warehouses.

The decision to cooperate:

The implementation of the Linker Cloud solution was a little challenge for both companies: the tool application concerned the largest online store, which handles approximately 70,000 orders per month. In mid-2019, when both companies started talking about cooperation, this number accounted for 70% of all orders managed by the Linker Cloud platform.

In addition, the implementation was combined as part of a larger project, which involved the replacement of the ERP system for the German company. A completely new environment of IT systems was designed, which on the day of product launch was supposed to take over the full volume of orders to be handled.

Implementation procedure:

Before launching the main point of the project, the customer wanted to be able to verify the operation of the system - its stability and reliability.

As a result, as the first stage, both companies jointly planned the implementation of a smaller-scale process, thus reducing project risks. The automotive industry leader chose the process of shipping goods to United Kingdom from the customers’ warehouse. The process was already based on communication with the new ERP system implemented for the DE process. The same applies to basic communication regarding the exchange of orders with the WMS system. The customer and Linker Cloud completed the first stage in April 2020 and, during the stabilization period, work on the second stage devoted to servicing Motointegrator.de started.

Despite the use of standard OMS functions, Linker Cloud built a scope that also defined many novelties:

- complex communication with WMS used to settle the issued goods along with the handling of shortages, surpluses and handling of automatic orders,

- separation of the process of handling single-item and multi-item orders,

- separating customer demand into several locations,

- creation of a new sorting module in Linker.WMS, in which we divide the goods from collection containers to dedicated litter boxes to which the goods from the selected customer order go;

- creation of a new transfer module for packing in Linker.WMS, which lists the finished orders in the rack and allows them to be passed on to the packer,

- dedicated model for handling discrepancies in the packaging process,

- shipment palletization module

At the end of November, the first tests of the solution with automation took place, in which companies tried to reproduce the production load of the environment. The tests that took place locally at the Regional Distribution Center and had to start after the end of production work - were held on Saturday evenings.

In part, the company based them on handling real goods from customers' offers, and in the other - on substitute packaging. The company invited warehouse employees who were the ultimate ones to handle the process. This was temporarily associated with the greatest severity of the COVID-19 pandemic. During the tests, not only the customer’s design team met on-site, but also the supplier's team. The tests allowed them to identify the critical points of the process that could only be seen on a large scale and to put the solution in the hands of target users. There were also applications for adding tools to monitor and control activities performed in Linker. This resulted in the extension of the scope of the project and the postponement of the launch date. The decisions made by the Steering Committee were very good and were primarily aimed at so-called SAFE START-UP.

In total, there were 7 sessions of such tests. The production launch took place at the beginning of February 2021. It may sound like a standard formula, but it was exemplary and without any significant problems that could delay the preparation of shipments.

.png?width=500&height=722&name=Wojtek%20Ciolko_2%20(1).png)

Cooperation with the customer team gave us a lot of fresh perspectives on operational problems in a company with a large scale of operations.

Together with the team, after many workshops, we developed processes and changes that significantly improved the most important metrics of success.

Wojciech Ciołko

CTO, Linker Cloud

Great cooperation reflected in the results

The Linker Cloud implementation was a strategic project for the client.

It was one of the projects with a quick return on investment, mainly due to the previous process that had great optimization potential. The Automotive industry leader had also added investment in new warehouse automation, which significantly limited manual trolley transports in handling B2C DE orders.

Assuming five-year depreciation for the warehouse infrastructure, the results in an ROI of 1.45. outperformed pre-project forecasts. It is worth emphasizing that this is not the end of the planned optimization. The company is working on increasing the volume of processed orders by transferring new sales channels.

Summing up

Working with market leaders is the best way to gain valuable knowledge and experience, from the product development perspective, but also adaptation and learning of the whole operational team. Final results shows, that even for such an advanced, well-organized, big company, there is still room for potential optimization in many areas.

>

2

years of successful cooperation

32

%

logistics cost optimization

📦

dropshipping model additionally implemented

2,5

mln

orders handled

If you are looking for fulfillment partner you are in good hands now.

Fill in the form to get a custom-made offer and see how you can start scaling into new markets soon.