In order to answer your request, we are obligated to process the data given above. Sometimes, however, we would like to use them for slightly different purposes, such as statistical data or informing you about our new products and services.We promise that we will use the given information for communication purposes only. We also remind you that you can unsubscribe from our mailing at any time (see Privacy Policy).

Expectations and requirements for logistics services are becoming higher each year, and every company involved in order fulfillment struggle with being challenged by the market and customers. Innovative tools, fulfillment networks, sales channel diversification - the industry is changing dynamically, but there are some traditional processes that can't be skipped or replaced. One of those is order picking at the warehouse, which may definitely change the final impression of the whole service.

Let's have a look at picking strategies, picking methods, and best practices.

What is warehouse order picking?

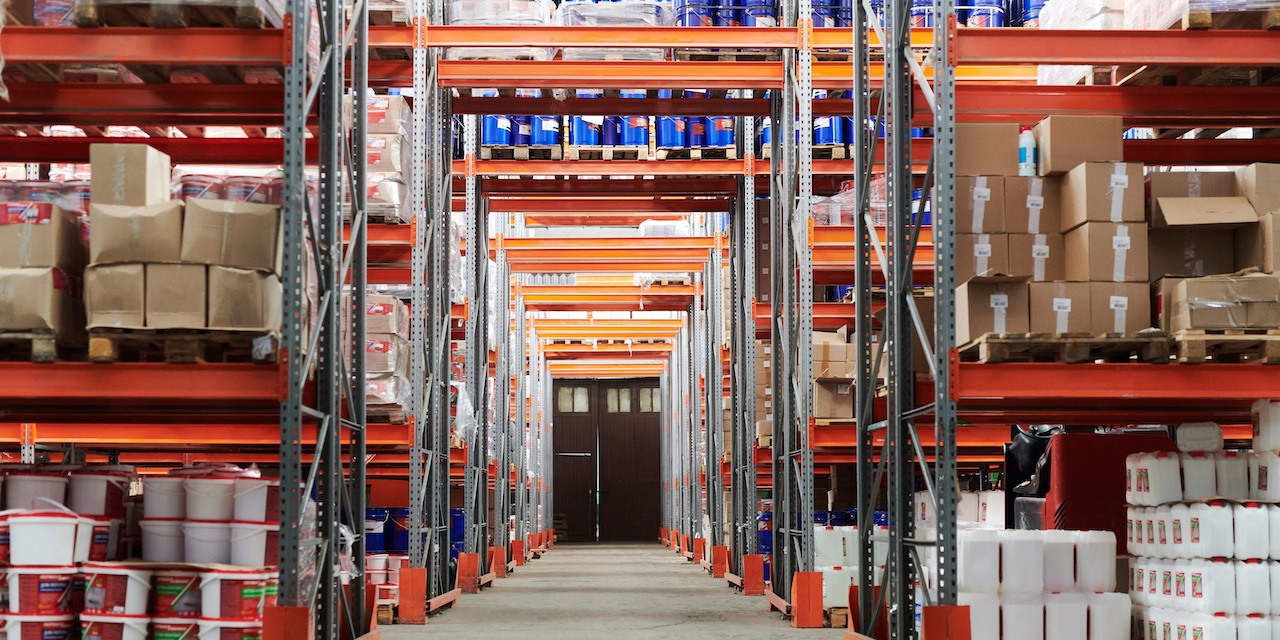

The picking process is a phase of the order fulfillment process, where the products ordered are being collected from the racks of the distribution center or warehouse shelves. It's the action that warehouse workers must complete before the final package is prepared and sent for the next step.

The process consists of such activities as organising the products in an orderly manner, then following the steps to pick all the products and transporting them to the packing station.

Sounds like the easiest job on the earth? Well, it's more complicated than it sounds and requires really good strategy and workers training, because bad order picking may bring huge damage...

Is order picking important?

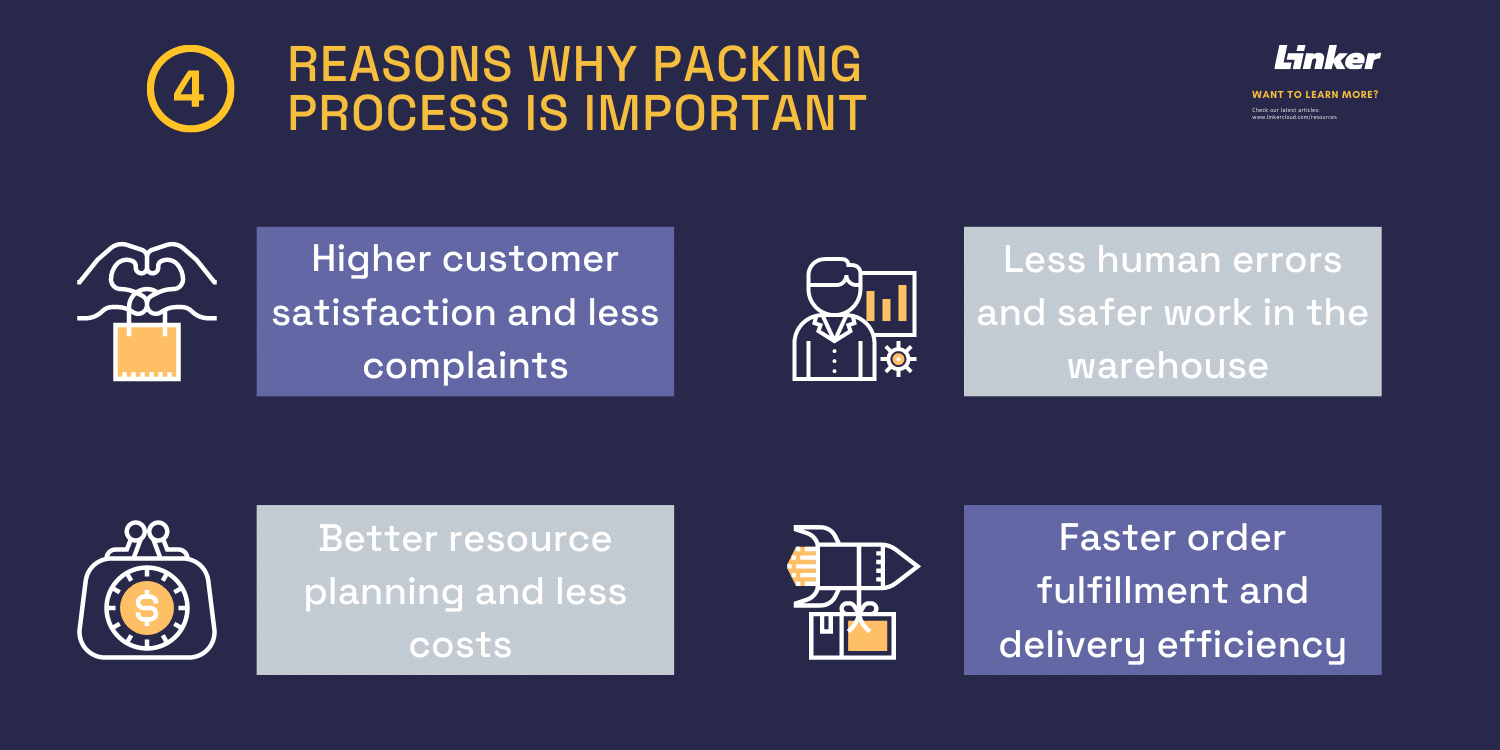

If we take look at the average operational cost of the warehouse's operating costs, we can discover that the picking cost is even more than half of the whole amount... What does it mean? That is probably the most crucial part and for some reason needs a lot of resources to ensure the right level of service.

A bad picking strategy will cost us a lot of money, that's for sure. "Bad" means designed in the wrong way, not adequate, devoid of proper analysis. Even if the final result, i.e. the correct completion of the order will be satisfying, poorly designed individual phases of the process can result in enormous costs, which in turn will directly affect the competitiveness and price of the service.

Even worse if the final result is a disaster: the customer receives the wrong package, with missing items, or items he didn't order, or some of them are destroyed. We risk immediate dissatisfaction, complaints and we risk a lack of future purchases from the client. For sure they will also spread the bad word to their friends.

It's also worth mentioning that well-organised picking processes are crucial for warehouse safety.

So, replying shortly if the picking process is important and worth the right resources and good planning - yes. It's a must.

Main picking strategies

Organising the warehouse picking process can be done based on already known and tested warehouse picking strategies. Which way is the best? Is it possible to calculate the time and cost for the selected picking strategy?

All the methods have their own pros and cons, and there is no one-fits-all solution. The process of selecting, or designing the right picking strategy is usually a long one and requires the involvement of supply chain executives and experts. Almost everything can be calculated, so after initial analysis, you will know the cost, time, resource usage, labor costs. However, we won't go into those details today, it's enough to mention that the most important factors for choosing the right strategy are the number of warehouse operations, the number of products (if only a few SKUs, or a lot), what are the warehouse space possibilities, and what are your current human resources.

Here are the most popular picking strategies, check them out.

Zone picking

A warehouse is divided into zones, and each zone has pickers assigned to their area. Zone picking is also known as "pick-and-pass", as after completing the picking process in one zone, the order is handed over to the next one. The package, before completion, goes through something like an assembly line.

Such a warehouse picking strategy allows workers to be very well versed in their territories, so the items are being collected quickly. Moreover, in zone picking, the areas can be organised by the characteristics of the products and fully adapted to move them (big-small ones, fragile ones, etc.).

However, it's hard to predict how busy each zone will be, so some of them may become the bottlenecks.

Batch picking

In batch picking strategy we seek to optimise picking processes by decreasing the distance the picker has to travel. Similar orders are being matched and assigned to a worker - he visits the appropriate zones completing all of them at the same time.

With this strategy, there is no need to travel many times to the same place, which is probably the most annoying, tiring, and time-consuming action.

Wave picking

This one strategy is a bit more advanced and complicated, compared to zone picking, or batch picking strategy.

The time of the process is being synchronised with stocking operations, delivery, and shipping time, to ensure the most efficient picking. The orders are not being assembled as they come, but they are being grouped by the same SKU and sent for completion in waves.

Wave picking strategy is often a part of big warehouse management systems, where there are many products, of different sizes, and multiple orders have to be served. It requires multiple scheduling windows and aligning all warehouse processes.

Discrete picking

This method is the opposite of wave picking and is good for smaller players, where a warehouse management system is not developed yet. What does discrete picking look like?

It's simple, the order is being collected as it comes. A worker picks all the items and packs them for final preparation, having to travel for the selected product each time it appears in the order.

How can I get faster at warehouse picking?

A right picking and shipping operations are not enough to ensure warehouse productivity. There is so much more to do around picking operations, to boost warehouse efficiency. Starting from choosing the right warehouse management software, through other process improvements and proper workers training can bring huge profits to your supply chain management system.

Here are some best practices regarding order picking.

Set up the goals

It's easier to manage the process if it's measurable and monitored. Warehouse managers should set the right goals for their teams to ensure the short time of completion along with minimising the picking errors.

The goals have to be realistic - if warehouse operations are not ready yet for partial automatisation and there are still places with paper-based picking methods then we shouldn't expect high efficiency.

But having implemented, for example, batch picking, we can expect the workers to improve at order picking, by for example reducing the distance.

Choose the right system

As mentioned above, there is no improvement without investing in the right tools. Systems and automation are one of them, and in order, picking issues are absolutely crucial. You won't implement a wave picking strategy if you don't have software that consolidates data about the entire warehouse.

There are also many more methods to deal with order picking like for example voice picking, where the team uses the support of headsets and hand-free systems to communicate around the warehouse area.

Operational excellence

The supply chain is a part of the order fulfillment process that generally requires high operational excellence. All the information has to be updated in no time, accurate and transparent, as there are a lot of operations ongoing simultaneously. Inventory accuracy is also very important - try to imagine an order picking process where there is an unexpected lack of the product, and all the processes can't be fulfilled.

There are many phases in which a little error can cause huge consequences. Not only order picker accuracy is something that makes the process successful, but it also has to be faultless from the inbound of the products till the last phases as printing shipping labels. Precise pieces of information available for everyone involved in the process improve accuracy significantly.

Be flexible

Not everything can be predicted, therefore make your strategies and systems as flexible as possible. Flexibility is the key to customer satisfaction in almost every area, also when it comes to warehouse order picking.

The picking method should support the agility of your business, and not always the most advanced one will be the best. Sometimes a discrete picking may occur to be the best, it all depends on the type of the business.

Quick summary

In the last paragraph, we would like to highlight once again that order picking is an extremely important warehouse operation, and should be well designed. It will help you reduce labor costs, time, and maximise the warehouse resources.

Advanced fulfillment centers or storage locations are the masters of warehouse order picking, therefore if you struggle with warehouse order picking, consider outsourcing it to the 3PLs.