In order to answer your request, we are obligated to process the data given above. Sometimes, however, we would like to use them for slightly different purposes, such as statistical data or informing you about our new products and services.We promise that we will use the given information for communication purposes only. We also remind you that you can unsubscribe from our mailing at any time (see Privacy Policy).

Logistics and the whole supply chain stand for transport and warehousing. What's more, they will continue to develop to meet the growing needs of e-commerce - and at the same time optimize costs. Gartner predicts that by the end of 2026, as many as 75 percent of large companies will have introduced some form of intelligent intralogistics robots. This major change will inevitably also affect companies that outsource their logistics - and thus this and other modern technologies will become a permanent feature of virtually all distribution centers.

But will this be the end of technology development in warehouses and supply chains? Welcome to our subjective overview of the most effective and interesting automation solutions - from OMS to video packaging recording!

Warehouse technology: the cornerstone of the new supply chain

Let me refer again to the Gartner data from the aforementioned report - according to the experts, AI (artificial intelligence) will soon conquer the supply chain as well. This, in turn, will mean that a quarter of the suppliers of supply chain solutions will have to revise the architecture of their microservices and adapt them to true composability.

Technology, on the one hand, is a challenge - on the other, it can be a life-saving option. Let us remember that successive warehouse management requires incredible amounts of data analysis, transparency, and also strategic planning. Only by combining all these elements into outstanding warehouse technologies can logistics act in the service of e-commerce and help online businesses continue to grow.

Efficiency is the key - you can improve it and achieve dramatically better results in several different ways, betting on tools to improve storage, packaging, or even... return handling. So let's take a deep dive into the warehouse operations topic - and see what new technology will occur most useful in the next few years from your business point of view!

Warehouse Management System

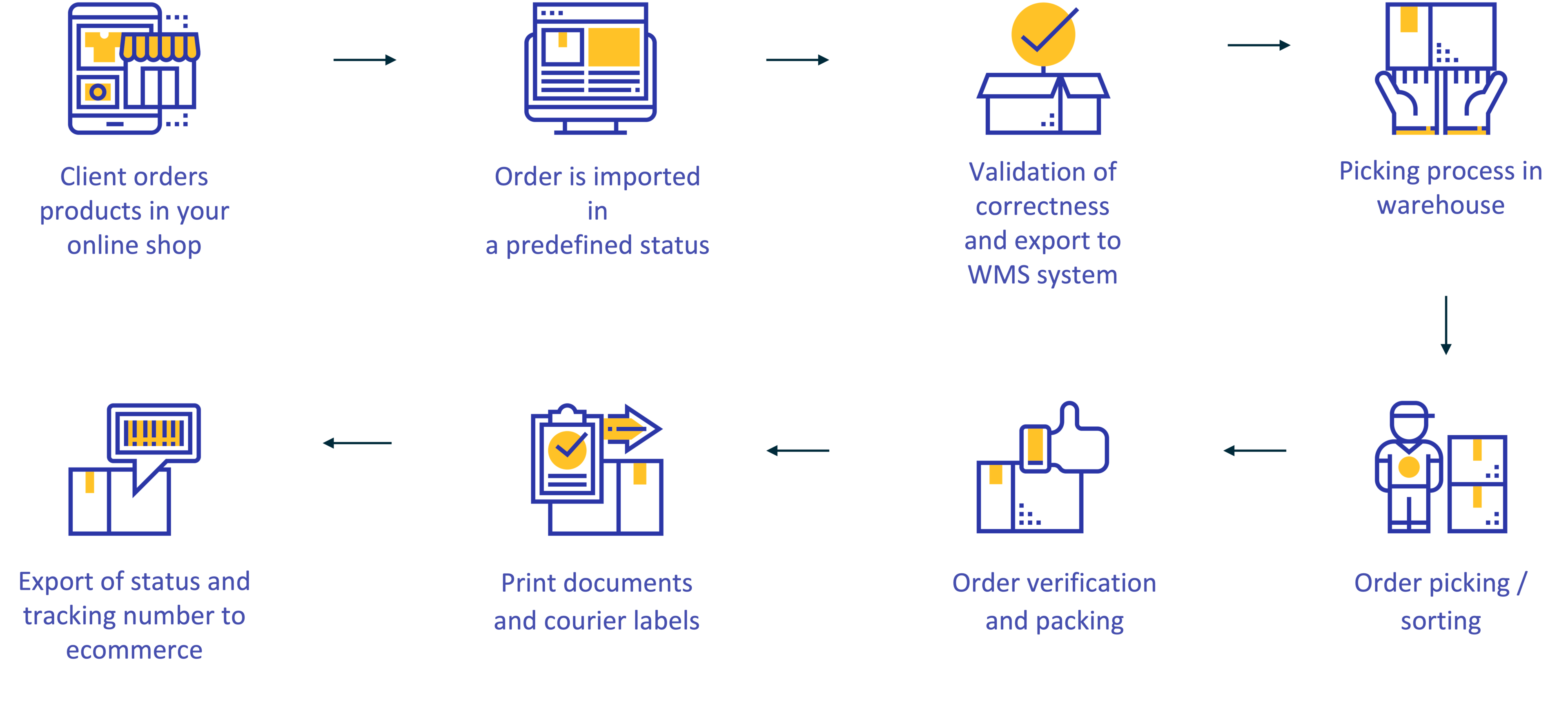

Let's start with the most obvious tool, the Order Management System, or OMS for short.

In simple words, it is a technology that allows proper data management, enabling comprehensive next-generation management of orders in the warehouse and getting higher productivity. It is based on the automation of processes regardless of the type of products in stock. It is used for order tracking, monitoring, and inventory management, and significantly facilitates reverse logistics and the packing, labeling, and shipping of goods.

OMS system is one of your modern business partners which provides sales support by preventing challenges such as overselling, problems with processing too many operations, or the mismanagement of storage space. In the bigger picture, it automates virtually every step of the logistics involved in an e-commerce warehouse and is reliable for business scalability plans, keeping an eye on the volume of the assortment sold and collecting all possible data on stock turnover.

It's a technology that you really can't miss in your warehouse. If you want to manage warehousing operations and your inventory wisely and successfully and meet the expectations of consumers, who not only want to receive undamaged goods - but above all to receive them quickly and without errors and sometimes to return them successfully, rely on this kind of instruction solution.

Supply chain: the power of storage and retrieval technology

Storage technologies are nothing new in the supply chain industry - however, modern versions of them perform far better than their older predecessors, allowing labour costs to be reduced while increasing accuracy levels, automating storage and retrieval processes in warehouses.

The basis of modern data warehouses are inventory management software - which also allows forecasting the level of inventory in real time and showing the view of their distribution in various facilities. However, this is not the end of the storage automation possibilities.

There are also automated storage systems, such as ASRS. Their task is to assist in the arrangement of goods for storage in accordance with the requirements previously defined by the warehouse. They also work well in the process of picking and consolidating orders - thanks to high precision and accuracy, they allow maximum use of storage space, significantly saving free space and at the same time minimizing the risk of damage and errors in the search, improving work throughput.

Another technology worth noting are the horizontal and vertical carousel modules, which improve the storage and retrieval processes. The horizontal option is based on the use of multiple containers rotating around the rack, being the ideal solution for storing small parts. Vertical carousels, on the other hand, are great for SKUs with slow to medium velocity. They allow for maximum use of high spaces and definitely better ergonomics.

Inventory scanning technology

Supply chain is largely based on keeping an eye on the goods. This of course also applies to warehouses - they must know their inventory, its exact location, tracking and retrieval processes. This helps to control the inventory problem and, if necessary, to make the necessary replenishments. Modern inventory scanning technology helps with this - helping to optimise the whole process and avoiding any mistakes.

Barcodes play a major role here. They contain all the data relating to product information so that the warehouse can easily determine what the product is, where exactly it is located on the shop floor and how many actual items of a given product are currently in stock, which makes it much easier to keep track of inventory. In addition, the tracking of barcodes also makes it possible to analyse the route that a parcel takes through the process of picking, packing, despatch and fulfilment.

At this point it is worth recalling a modern supply chain solution improvement - namely RFID systems. Thanks to the use of electromagnetic waves, they help keep track of inventory in real time. All a warehouse needs to do is attach RFID tags to products or packaging, and it can then easily monitor stock movements at all stages of storage. Compared to conventional barcodes, this technology does not require the use of scanners - allowing much better automation and reducing the time and effort previously spent on manual scanning.

Packing technology in supply chain

Packaging is one of the most important points of work in the warehouse - it has a primarily defensive function, but is also a great opportunity for companies to make their branding stand out.

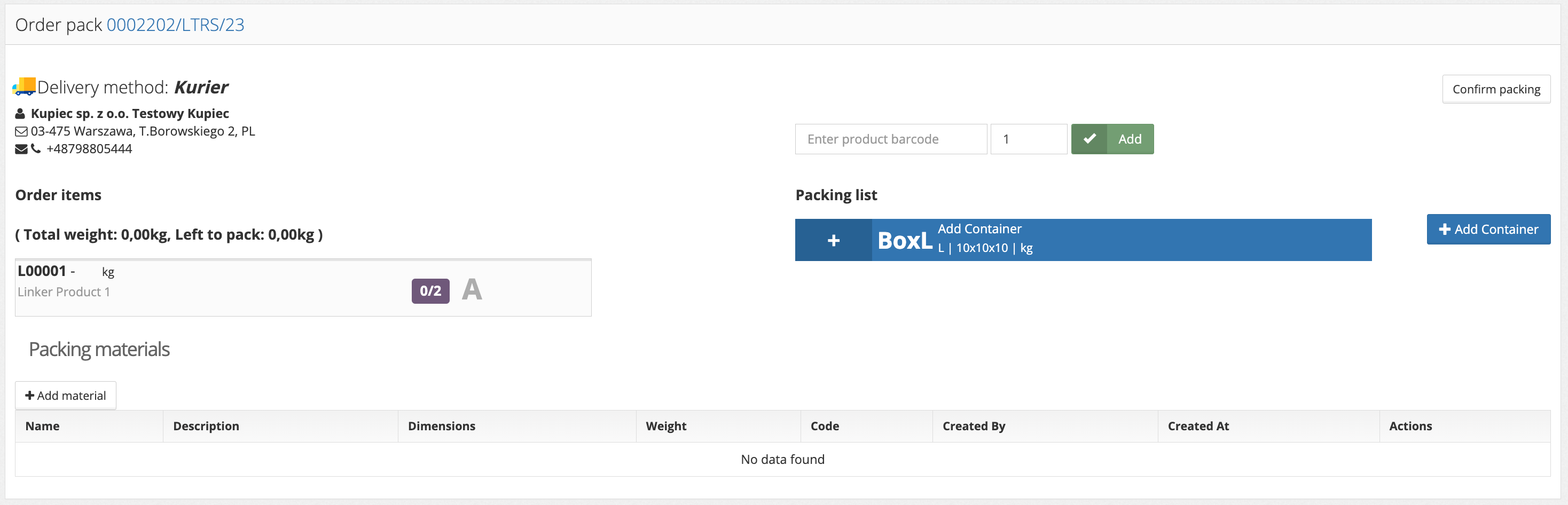

However, we do not hide the fact that implementing it 100% manually can be a challenge. Fortunately, in the warehouses of the future (and in some of the facilities already serviced today), there are solutions that allow the process to be automated, recorded (which can be extremely useful when dealing with returns and complaints) and even.... suggesting the size of the box that perfectly fits the goods.

Let's start with video recording of packaging. You have probably been in a situation more than once where you have had to accept a return from a dissatisfied customer. You often have no control over this - perhaps the colour of the product was not what they wanted, the goods were a different size or the customer simply changed his mind after ordering.

Worse still, if the customer complains that they received the wrong product or that the products were damaged. By opting for a VRoP system, you can firstly check the validity of your customers' comments, and secondly, analyse the process and, if it needs to be improved, implement the appropriate measures in warehousing operations.

But how does this work in reality? Firstly, let's talk a bit about the equipment. VRoP systems provider should offer assistance in the selection and purchase of appropriate equipment (cameras, DVRs, servers, etc.) along with support for the installation of cameras at packing stations. Than, it needs to provide the software that controls the cameras and start recording with the start of packaging end we end recording when the shipment is closed and labelled.

In Linker Cloud solution you'll have an access to the recording from the order level where you will find a photo of each packed package. Each recording is tagged with the product information that was scanned during packaging, allowing you to instantly get to the part of the recording you need.

Material prompting module

Modern warehouse operations systems therefore not only reflect current stock levels and gather all order information in one place (order history, quantities delivered and even courier statuses), but also have additional functions, such as recording materials used for packaging or suggesting the optimum and accurate carton for packing an order - which in the bigger picture allows the lowest material costs to be maintained even with a rotating workforce.

In addition, for modern e-stores' clients, it is also extremely important to take care of issues related to sustainable supply chain. Keeping records of the materials used and recommending the most suitable ones are decisive in this respect, as they limit the use of even unnecessary fillings and contribute to reducing waste. What's more, this is a real win-win situation - because not only do you promote an environmentally friendly approach, but you also significantly reduce the cost of materials which you may not use.

Improve your supply chain technologies and connect with a logistics experts today!

As you can see for yourself, today's data warehouse products are much more than the ability to load data and observe the analyses generated. Modern automated technology has improved almost every area of your warehousing operations.

All you need to do is rely on reliable business partners who will take care of your logistics like true professionals. Such a company will help solve retailers with their logistical challenges and problems by selecting the right infrastructure for your needs.