In order to answer your request, we are obligated to process the data given above. Sometimes, however, we would like to use them for slightly different purposes, such as statistical data or informing you about our new products and services.We promise that we will use the given information for communication purposes only. We also remind you that you can unsubscribe from our mailing at any time (see Privacy Policy).

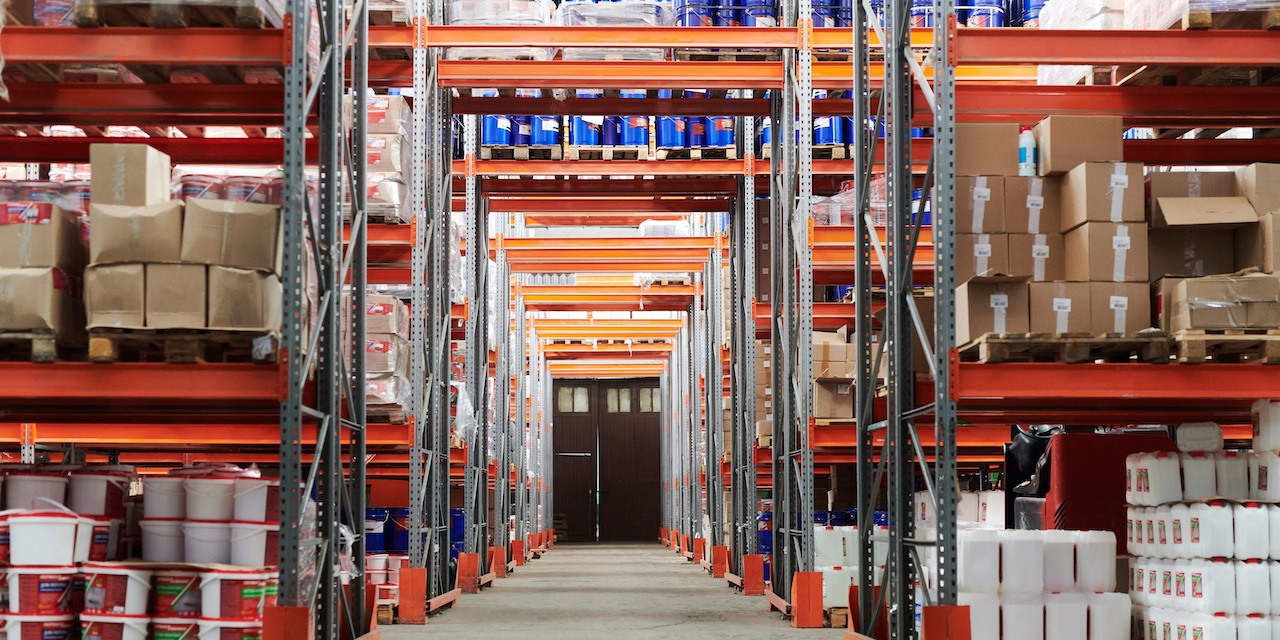

At a time when global consumption of goods is peaking and probably will grow by 8.1% in 2021, according to Deloitte forecasts, the warehousing industry is faced with an extraordinary amount of work.

It is certainly not the easiest or safest work, because still many hazards are present in the warehouse environment. The basis of a quality workspace is not only ergonomic work but also safety measures to prevent serious injury.

What does warehouse safety mean?

Warehouse safety is defined as a set of rules and best practices aimed at providing a safe working environment. As storage work is to a significant extent based on human labour and the use of appropriate equipment, the observance of the relevant rules and occupational safety becomes a key factor.

More importantly, the balanced and smooth running of the warehouse depends on safe working practices, which is why it should be a priority for management and warehouse owners. According to data prepared by Eurostat, based on information collected from European Union countries, fatal accidents at work in the transport and storage sector in 2018 were the second highest in number. These studies prove that the problem is real and warehouse safety programs are simply necessary.

_AAW2020.png?width=686&name=Fatal_and_non-fatal_accidents_at_work_by_NACE_Section%2c_EU-27%2c_2018_(%25_of_fatal_and_non-fatal_accidents)_AAW2020.png)

Most common warehouse injuries

As we mentioned, the transport and storage section are in second place in terms of fatal accidents. When it comes to severe injuries it is not so bad, although it is still around the top five. Serious accidents are defined as those which result in at least four calendar days of absence from work.

The most common injuries among warehouse workers are:

- falls,

- trips,

- collisions with forklift trucks,

- exposure or contact with hazardous materials,

- but also slips and falling objects.

To avoid such situations, you need proper procedures to minimize the risk of accidents and injuries to workers and to ensure their health and safety.

10 warehouse safety rules

We have compiled a list of principles based on best practices and available knowledge, to help ensure health and safety at work:

Personal protective equipment (PPE)

One of the most essential elements of work-related injuries at warehouses or distribution centres is right PPE provided by the employer. This includes safety shoes, high visibility jackets, safety glasses, and gloves.

Lifting equipment

Warehouse work is based on moving goods, stacking, or collecting products from various locations. To improve work efficiency and reduce possible back injuries, workers should use lift trucks to ease the handling of massive quantities of goods.

Potential safety hazards

It is worth looking out for elements that can be dangerous during work. Wet warehouse floors can cause slip hazard or uneven surfaces can cause falls, impacts, or trip hazard. To follow these rule employees must be aware not only of their own safety but also of the safety of others, by paying attention to warehouse cleanliness.

Danger zones

Clear markings and stickers are an effective way of reminding people of possible dangers. Warning signs should be placed where proper precautions are needed, or specific rules must be followed. They can remind what activities are prohibited or what equipment is necessary (e.g., hard hats). Such marks can prevent serious accidents among workers. Signs should also be provided to show emergency exits and assembly points in case of a fire.

Education and training

Very often people are the most unreliable element in a safety situation. To avoid such scenarios, you need to focus on warehouse employees' proper training. This includes safety regulations and emergency procedures for the entire warehouse as well as job-specific training that helps to understand the risks and ensure the safety of the individual.

Forklift safety procedures

As mentioned earlier, the use of machinery and vehicles such as forklifts and lifting platforms is practically indispensable during warehouse work. However, the risk of crush injuries posed by these vehicles is also real. Therefore, the use of equipment should only be taken by people with the necessary qualifications and after extensive practical training.

Another aspect of vehicle safety will be speed limits within the warehouse to protect workers.

Safe storage

A characteristic of a well-managed warehouse is the correct organisation of the stored goods, depending on the type, size, weight, or conditions in which they should be kept. The shelves and storage areas should be easy to access, to collect items efficiently and at the same not overloaded to avoid mess and danger of falling objects.

Fire Drills

Nowadays, fire protection systems are a fundamental part of the warehouse safety program. Due to the variety of risks present in a warehouse, such as chemical hazards or storage of dangerous materials, smoke alarms, emergency lighting, and fire alarms can save many lives.

The warehouse should have at least two well-marked and designed emergency exits which are regularly checked for operational features and safety performance.

Besides an effective fire system, committed and aware people who know the procedures to follow in case of emergency are needed. Regular employee training and fire drills will help to reduce the number of dangerous situations and achieve a safe rescue operation when necessary.

Air circulation

Sometimes efficient ventilation is overlooked when it comes to safety. But proper air circulation eliminates the accumulation of unwanted gases and improves the quality of work. That is why investing in a suitable exhaust system to improve the ventilation of the warehouse is crucial.

Equipment servicing

As the equipment is a major part of safe warehouse work, its quality must be guaranteed. This applies to both the protective equipment used by employees and the devices used at work, like powered industrial trucks. If the machinery is checked, repaired and in good condition, safety will be significantly improved.

How to improve warehouse safety procedures?

The advice given above provides an excellent basis for further upgrades. Once you are satisfied with the results achieved in the first stage, you can move on to the next steps in the safety plan, like:

First aid

Besides ensuring that your employees are trained for their positions and have access to first aid kits, you should also organise first aid training. These courses are provided by medically trained people, often by lifeguards, who teach the right reactions. In a warehouse environment, this can be necessity in an emergency.

If you are not sure how to implement changes related to medical access in the warehouse, you can ask the health administration or other relevant authorities in your country for help in preparing specific guidelines.

Designated smoking area

Do not assume that all warehouse staff will be non-smokers. To avoid the potential fire hazards, designate a smoking area away from ignition sources. A zero-tolerance policy is also needed, and smoking should only be allowed in a specific area. Otherwise, employees may try to ignore the rules.

3 metres rule

In warehouses where pedestrian traffic is mixed with moving equipment (e.g., pallet trucks), it is worth introducing the 3-metre safety rule. This means that an area of 3 metres around powered equipment or machines must be kept clear of traffic. This helps to avoid serious injuries to pedestrian workers. Signs or warning stickers on equipment can also remind people of these rules.

Summary

Maintaining safety standards in the warehouse is a continuous process, largely based on people, safety equipment, proper ergonomics, and control measures. Taken stages should be well planned and executed step by step. We hope that the advice given will prove useful and help to increase warehouse safety.